|

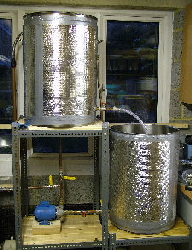

HLT and Mash Tun are stainless steel tanks with a rim capacity of 100lt.

The HLT has a 3kw immersion element and will be linked to a timer control to allow overnight heating on cheap rate electric.

New control panel will house the PIDs and electrics for HLT heater and sweet wort pump.

Click the year to jump down the list of updates - 2007 2008 2009

|

Progress

|

..and the pictures!

|

|

Mid May 2007

All old kit re-installed

Secondary consumer unit for garage & brewery power

Dexion racking built to hold new SS HLT & Mash Tun

|

|

|

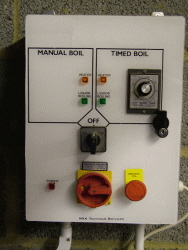

Copper control panel

Timer has a 60min dial so is ideal for planning the various stages for hop additions.

|

|

|

....and inside !!!

Looks like a job for the professionals!

|

|

|

Copper for boiling the wort with the hops

|

|

|

...and inside...

3 x 3kw elements are available but only 2 are used as the supply cable to the garage/brewhouse is only 6mm.

|

|

|

Fillter and pump

|

|

|

Finally the massive heat exchanger

You want fast wort cooling, you got it!

|

|

|

Gas Management Board.

Regs for both CO2 and 60/40 mixed gas.

|

|

|

HLT also contains the HERMS wort heating coil made from 10mt of 10mm soft copper

|

|

|

July ... nearly ready!

HERMS coil all in place together with 3kw immersion heater and max level float switch

|

|

|

HLT and Mash Tun in place.

Each tun has a foil backed camping mat as the first insulation layer.

Pump is used to re-circulate the wort via the coil in the HLT keeping the ideal mash temperature.

Mash tun now has pine cladding over the mat.

HLT is to follow soon.

|

|

|

Mash tun strainer in 1mm perforated stainless steel.

1x large top folded in the middle

2x triangle ends fixed with ss wire

Pickup tube to collect from the bottom of the mash tun.

|

|

|

Finished item in place and ready for a test brew.

|

|

|

More additions - January 2008

Fermentation chamber made from old kitchen cabinets with foiled PU insulation slabs.

100w tubular heater to keep the ‘yeasties’ at the ideal temperature..

Next stage is to hook some kind of cooling system linked to a bar cooler so i can keep brewing in the summer.

|

|

|

The control box - ATC800 will manage both a heater and a cooler.

Ambient temperature in garage 8c and the inside holds a steady 19-20.

|

|

|

March 2009 - at last!

New control panel for the HERMS and HLT

Digital timer control, Pump speed control, PIDs for each temperature control plus AUTO and MANUAL indicators and switches.

|

|

|

Bottom of panel has two 16A sockets to connect the heater and pump.

Also has the two sockets for the thermocouple leads.

Circuit 1 - immersion heater for HLT

Circuit 2 - pump control for HERMS.

Click here for the

wiring circuit diagram

|

|

|

|

|

|

Planned and due very soon!

High level water alarm for the HLT -

i’ve had to many overflows when collecting the hot return water from the heat exchanger :(

Further insulation on HLT and wood cladding to match the Mash Tun.

Also need to decide how to build and fit the cooling device for the fermenters.

Maxicool 100 flash chiller is ready for action!

|

|

|

Back to the top

|

|

|